Chinaplas2023 | Siiico Technology invites you to jointly launch a new future of UHMW-PE processing!

Date:

2023-04-21

On April 17, the high-profile Chinaplas 2023 International Rubber and Plastic Exhibition was held in Shenzhen World Exhibition&Convention Center (Bao'an New Hall). Siiico Technology Co., Ltd., with the world's first new efficient and intelligent ERE extrusion equipment that can easily achieve the extrusion of ultra-high molecular weight polyethylene sheets and the production line of ultra-high molecular weight polyethylene pipes for home decoration, made a brilliant debut at booth 6B31.

▲Siiico Technology Booth (6B31)

The ultra high molecular weight polyethylene sheet extrusion production line launched at this exhibition and the new ultra high molecular weight polyethylene pipe extrusion production line used in the construction industry for home decoration are both developed and manufactured based on the patented technology "Polymer Material Plasticization and Transportation Method and Equipment Based on Tensile Rheology" (referred to as ERE technology) owned by Siiico Technology Co., Ltd., which is dominated by tensile deformation and has strong transportation and plasticization capabilities The advantages of strong mixing and dispersion ability can overcome the processing difficulties and low production efficiency caused by long molecular weight, high viscosity, and poor flowability of ultra-high molecular weight polyethylene, achieving efficient and high-performance extrusion.

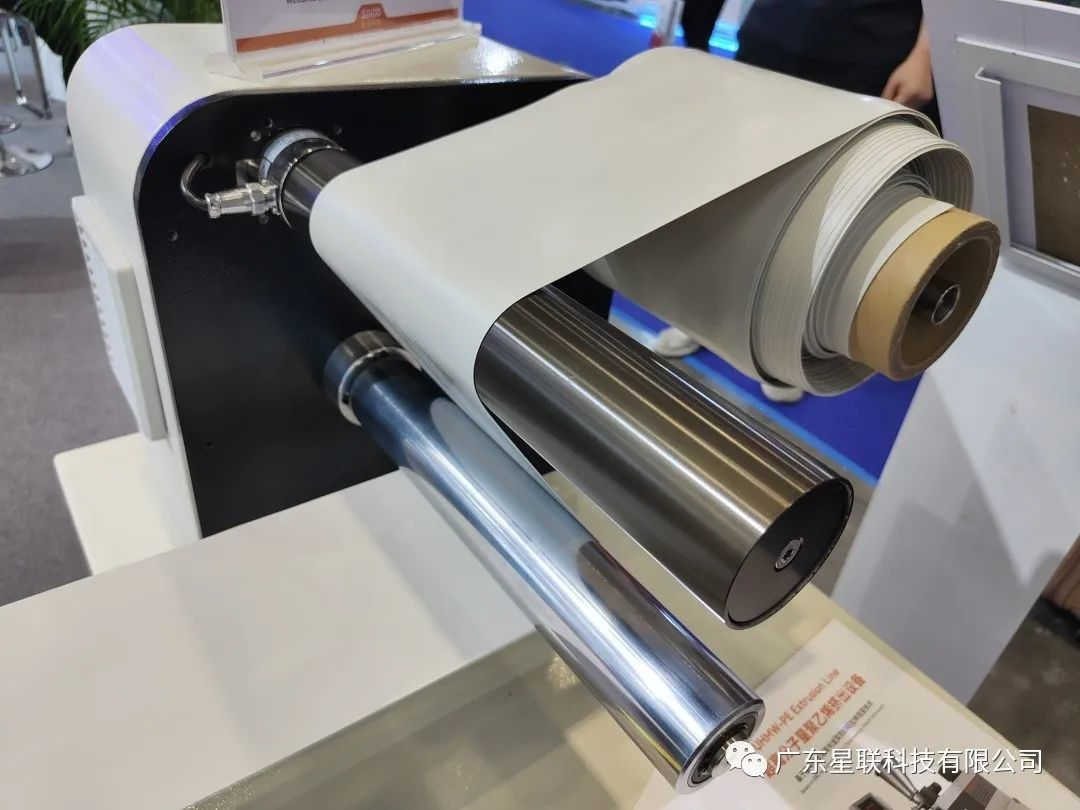

Ultra high molecular weight polyethylene sheet production line

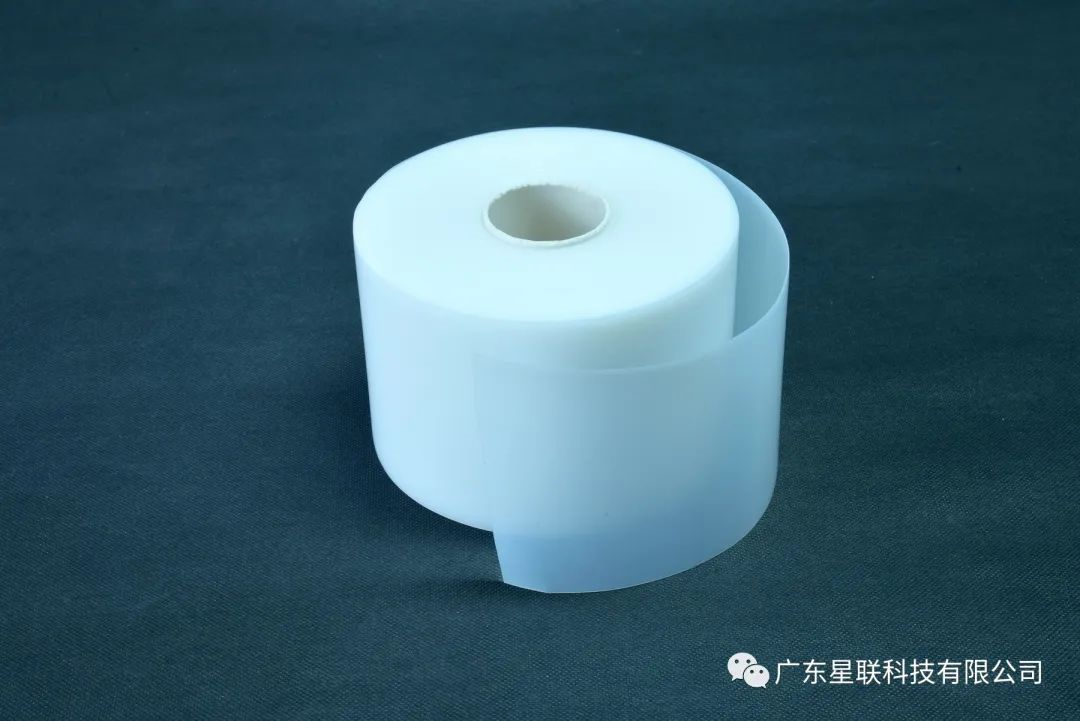

The production line of ultra-high molecular weight polyethylene sheets fully leverages the mixing and dispersion advantages of our company's ERE technology, which has won the Chinese Invention Patent Gold Award, in extreme rheological materials, achieving continuous extrusion of ultra-high molecular weight polyethylene sheets.

The new production method of ERE extrusion molding can replace the traditional sheet production method that requires later cutting and molding in the industry, greatly shortening the product thermal process, reducing intermediate processes, improving production efficiency, improving product quality consistency and stability, and improving product performance. At the same time, the continuous extrusion processing method solves a major problem of limited length and thickness of ultra-high molecular weight polyethylene sheets in the industry.

The products produced can be used for working surfaces that require sliding, such as foot mats, insulation materials, wear-resistant gaskets, furniture gaskets, slides, wear-resistant panels, etc.

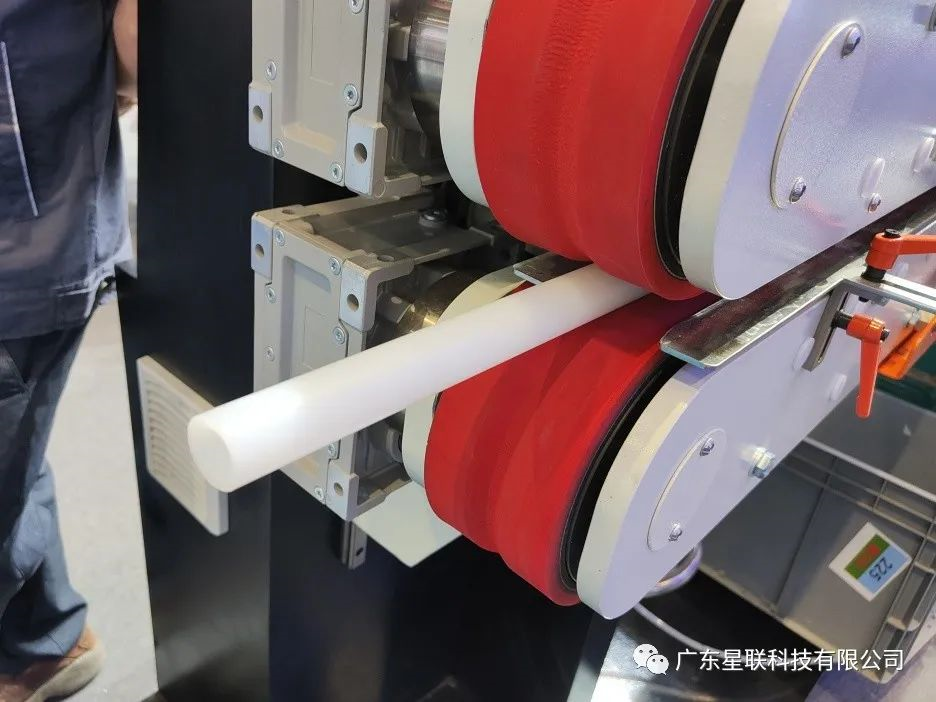

Ultra high molecular weight polyethylene pipe production line

Ultra high molecular weight polyethylene is an ideal pipe material. The new extrusion production line of ultra-high molecular weight polyethylene pipes for home decoration, jointly launched by Xinglian Technology and related enterprises, is used in the construction industry for the first time. The equipment is stable in extrusion, and the surface of the products produced is smooth, with extremely high comprehensive performance.

Ultra high molecular weight polyethylene pipes have excellent low-temperature resistance, allowing them to maintain stable working performance in extremely cold regions and can be used normally in different climatic conditions.

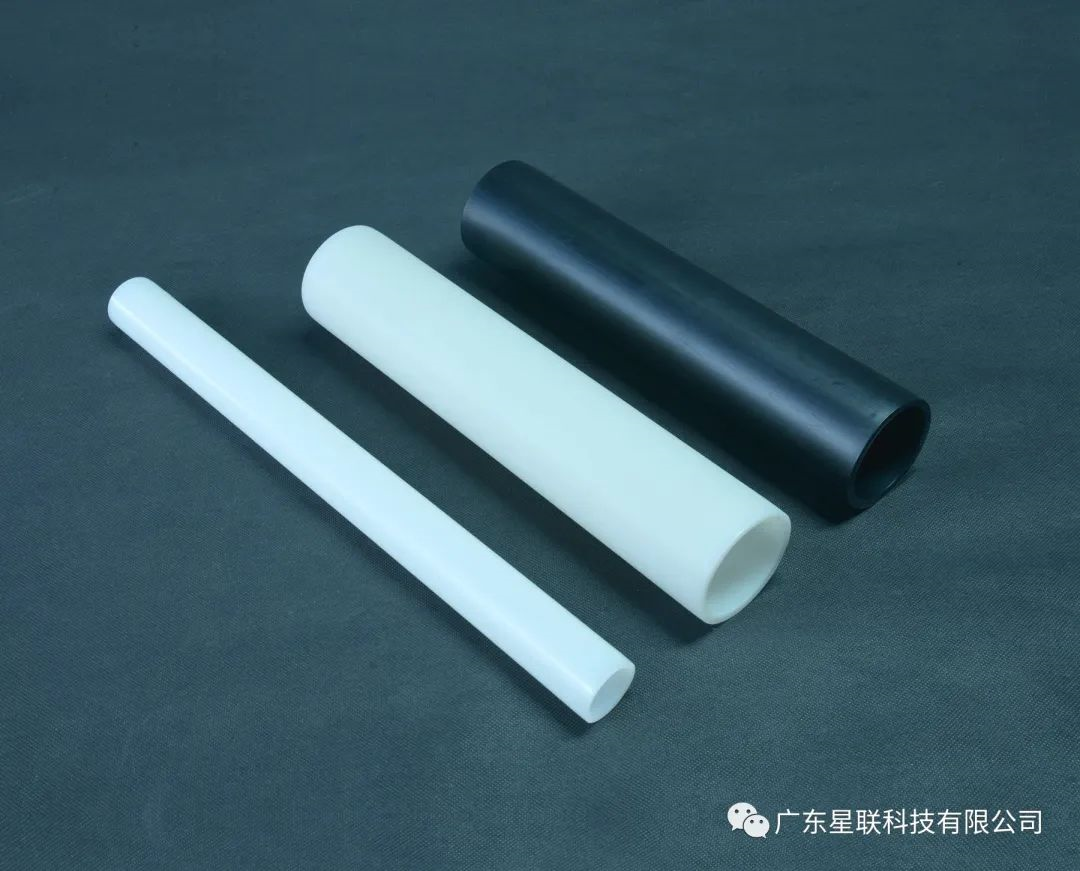

At the same time, ultra-high molecular weight polyethylene products that have achieved efficient and high-performance extrusion are also exhibited. The products produced through a new type of ultra-high molecular weight polyethylene extrusion equipment have high surface gloss, good self lubrication, excellent wear resistance, and excellent mechanical properties. They can be widely used in transportation machinery, food processing, packaging machinery, marine aquaculture and other fields, reducing energy consumption and noise, improving product service life, and improving product quality.

▲Ultra high molecular weight polyethylene products

The on-site response was enthusiastic, with waves of domestic and foreign audiences constantly pouring in. We were attracted by the ERE efficient and intelligent extrusion equipment that can easily achieve efficient and high-performance extrusion of ultra-high molecular weight polyethylene products, and on-site negotiations were lively.

▲Exhibition site

This exhibition is not only a platform for showcasing products and technologies, but also a networking event that brings Siiico Technology closer to well-known domestic and foreign enterprises, industry experts, partners, and potential customers present. The new extrusion equipment that overcomes the global challenge of "efficient and high-performance manufacturing of ultra-high molecular weight polyethylene products" has received unanimous recognition and praise from on-site customers and experts. Many industry giants and powerful enterprises have expressed strong cooperation intentions.

Chinaplas2023 has come to a successful conclusion. In the future, we will continue to adhere to the core values of "professional focus, co creation and sharing", with the mission of "promoting and popularizing tensile rheological technology, and continuously creating new fields of polymer material application", striving to become a leader in polymer material processing technology.

Related News

Copyright © 2020 Siiico Technology Co., Ltd. 粤ICP备16105518号  粤公网安备44060502001892号 Support: 300.cn dongguan SEO

粤公网安备44060502001892号 Support: 300.cn dongguan SEO