PRODUCT & APPLICATION

Focus on R&D, production, sales and service of intelligent manufacturing equipment for poiymeric materials and new high performance matrial.

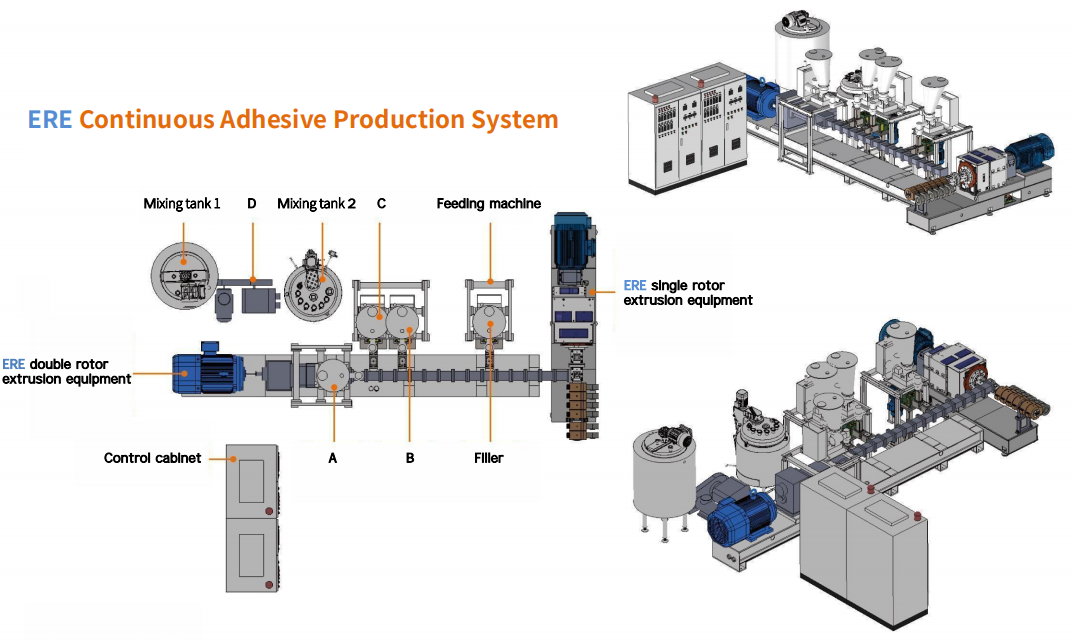

ERE Continuous Adhesive Production System

ERE Continuous Adhesive Production System

Replacing the intermittent production of reaction kettles, it is possible to integrate the production and application of hot melt adhesives!

my country's high-end polymer self-adhesive film waterproofing membrane market scale is more than 100 billion, the industry is growing

The space is very wide, but due to the intermittent reactor production method of hot melt adhesives, there is no method to automate continuous production: cooling, packaging, transport and The tedious and complex high-energy and inefficient processes such as reheating and melting cannot be realized with the waterproofing membrane production line.Coating in parallel, so the equipment consumes a lot of energy, costs high, and the consistency and stability of product performance are poor.

"ERE Continuous Adhesive Production System" plays the role of our company in winning the Chinese Invention Patent Gold Award

The mixing advantages of ERE extensional rheology technology for extreme rheological materials have replaced the polymer automatic in the industry.Hot-melt adhesives for adhesive film waterproofing membranes must be produced in batches using kneaders or reactors.

It can be connected with the coating production line of the end user to realize the continuous production of polymer self-adhesive film waterproof membrane.It makes it possible to integrate the production, application and coating of butyl hot melt adhesive, which will greatly shorten the production time.The thermal history reduces the intermediate process, reduces the production environmental protection requirements, and makes the product quality consistent.And stability improvement, performance improvement, cost reduction. "ERE Continuous Adhesive Production System" It will provide a complete set of solutions for large-scale waterproof enterprises and the conversion of original and newly introduced production lines into continuous productionProgram.

Comparison of traditional adhesive production methods and ERE continuous adhesive production methods

| Item | Traditional adhesive production methods | ERE Continuous Adhesive Production Method | ||

| Content | Cons | Content | Disadvantages | |

| Device | Reaction kettle (stirring kettle) | Cannot produce ultra-high viscosity products | ERE Extrusion Equipment | Wide viscosity window |

| Heating temperature control mode | Boiler heat transfer oil circulation heating and temperature control Different feeding stages require different temperatures | Advanced and accurate temperature control technology is required, especially electric heating, it is difficult to predict the advance, and the safety is poor | Electric heating combined with water cooling or air cooling to control temperature, and the temperature can be controlled by zone | Short heating time has low sensitivity to temperature and high safety |

| Production method | In the song style, after one batch is finished, the next batch will be produced | Product performance consistency and poor stability in different batches | Continuous extrusion production by precise metering of materials | Product quality is stable and consistent |

| Adding method. | There is a stricter material feeding sequence | Incorrect order may lead to production failure| | All materials are added simultaneously from different inlets | Different materials, different entrances are automatically added, not easy to make mistakes |

| Production method | Depending on the product process, the batch varies from 3-7 hours | Excessive heat treatment and production time lead to aging and heavy oxidation of raw materials | Design corresponding structures for different products, and the material residence time is 5-15 minutes and controllable | Short and controllable thermal history, better retention of original characteristics, wider formula design window |

Introduction to key processes

1. Component D, filler, component A, component B, and component C are metered into the ERE twin-rotor extrusion equipment through different inlets;

2. All materials are initially mixed, dispersed and melted in the ERE double-rotor extrusion equipment, and then injected into the ERE single-rotor extrusion equipment for further mixing and dispersion, and well metered extrusion;

3. ERE single-rotor extrusion equipment can be directly connected to the coating die for coating, and then directly rolled to make products.

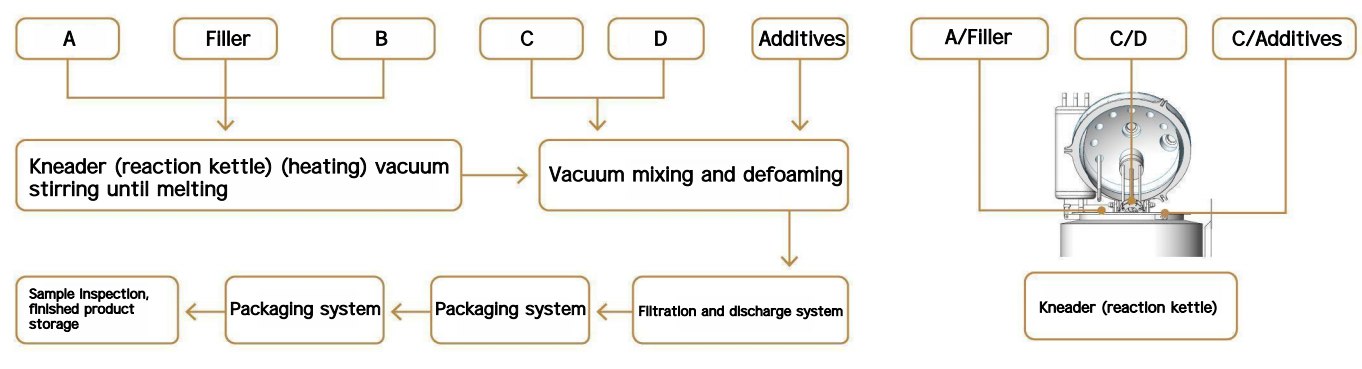

Traditional adhesive production process

Introduction to key processes

1. Add component A, filler and component B into the kneader (reaction kettle) in a certain order, heat to a certain temperature, and stir the material in vacuum until it is completely melted;

2. Add some components C and D, stir evenly in vacuum and defoaming;

3. Add the remaining components C and additives, continue to stir evenly in vacuum and defoaming;

4. Filter the products that have passed the preliminary inspection through the filtering and discharging system;

5. The filtered materials are measured and packaged by the packaging system;

6. Sampling during the discharge process, inspect the finished product, and pack it into storage after passing the inspection.

Related Downloads

Copyright © 2020 Siiico Technology Co., Ltd. 粤ICP备16105518号  粤公网安备44060502001892号 Support: 300.cn dongguan SEO

粤公网安备44060502001892号 Support: 300.cn dongguan SEO